|

SELLA TYRE SERVICE PRODUCT;

Scientific Proof on 150% TYRE LIFE:

A) Phenomena on tyres due to vehicle

�@operations:

1) Heat is generated in tyres travelling with a heavy load:

(1) Why is heat generated?

The vehicle can start, change course and stop at will thanks to the fricion of the tyres. What

would happen if the tyres had less friction?�@ Just think of the scene when driving on ice and

you will immediately understand. The vehicle cannot start or stop smoothly, and even if

you turn the steering wheel,�@ the vehicle will only go straight ahead without changing

course.�@�@ According to the definition of friction, A force is produced between objects in

contact with one another that opposes their action.�@�@ This force is called "the frictional

force and it is a force in the opposite direction that tries to move the object"�@�@ This frictional

force is classified into three types:

(i) static frictional force, which occurs when an object at rest is moved;

(ii) dynamic frictional force, which occurs during motion;

(iii)rolling frictional force, which occurs when the object is rolling.

The static and dynamic friction forces can be expressed by formulae,�@�@�@but the rolling

friction force has not yet been expressed by a formula because there are still many unresolved

points. For reference, the friction force can be expressed as f=��N, f'=��'N. f is the static friction

force and f'is the magnitude of the dynamic friction force. �@�� is the coefficient of static friction

and ��' is the coefficient of kinetic friction. ��'is smaller to ��.�@�@�@�@For reference, the larger the

coefficient of friction,�@�@ the greater the frictional force, and the smaller the coefficient of fric-

tion, the smaller the frictional force.

(i) Tyre (rubber) 1.36, (ii) Ice 0.01, (iii) Concrete 0.1~0.2

The high coefficient of friction of the tyre (rubber)�@ allows the vehicle to transport the

cargo freely and safely to its destination. However, as a compensation, the kinetic ener-

gy of the tyre is converted into heat energy, which makes the tyre hotter. Paraphrase it,

heat due to friction is work, so, work = force x distance,�@�@ and furthermore, distance =

speed x time, so work = force x speed x time = coefficient of dynamic friction x speed x

time. Dynamic friction force = f' = ��'N = coefficient of dynamic friction x load, only the

coefficient and load can change dynamic friction.

Therefore, the heat of friction increases when �@ the load is large,�@ �A the speed is high

and �B the vehicle runs for a long time. This is consistent with our experience. |

(2) What happens to the heat generated afterwards?

Tyres are rubber, and the thermal conductivity of rubber is 0.13, �@ indicating very low thermal

conductivity compared to the wheel materials steel 80 and aluminium 250.�@�@ Therefore, the

heat generated by the friction between the tyre tread and the road surface�@ is transferred a little,

most of the heat that is not transferred is concentrated and stored in the tyre tread. In oth-

er words,�@�@�@the heat that does not move is accumulated in the tread area as excess heat.

Therefore, the temperature of the tyre will continue to rise.

2) The cooling effect of wind on running tyres works:

Running tyres generate heat due to friction, but at the same time there is a cooling action

by the wind. This is the same as cooling an air-cooled engine. In other words, the tyre is a heat

sink.

Let's take a look at how much cooling power a running tyre has.

The Japan Society of Mechanical Engineers (ed.), Electrothermal Engineering Materials, Revised

Fifth Edition (2009).

Natural convection (stopped): forced convection (running).

�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@�@ Water �@�@�@�@�@�@�@ �@�@ Air �@�@ Units: w/(m2 K)

Forced convection: �@�@�@ 1000 ~ 10000 �@�@�@�@�@ �@ 10 ~ 100

Natural convection: �@�@�@�@ 500 ~ 1000 �@�@�@ �@�@�@�@�@1 ~ 10

This data shows that when running,�@the cooling power is 10 ~ 100 times higher than that of

natural convection(stopped). In other words, the heat generated by the friction of the tyre and the

cooling by the wind in forced convection - this is all that happens to the tyre while it is running.

In order to further deepen our understanding of tyres,�@ we will now review our knowledge of the

rubber and air that make up the tyre.

B) Natural rubber features:

1)The great invention by Goodyear in 1839:

Natural rubber is made from latex, the sap of the rubber tree. �@However, latex is not strong e-

nough to withstand industrial use.�@ But, the great invention by Goodyear was the vulcanisation

process for rubber. The vulcanisation process gave rubber excellent strength and elasticity.

However the biggest drawback of vulcanised rubber is ageing.�@ What is ageing? It is the

loss of elasticity and strength.

2) Three reasons for ageing:

(a) post-vulcanisation: (b) disaggregation and depolymerisation (c) oxidation by oxygen in air.

(1) Post-vulcanisation:

as vulcanisation progresses and over-vulcanisation occurs, the strength of the tyre decreases.

Even if the tyre is properly vulcanised, if it is left in the air, vulcanisation will progress and the

tyre will eventually lose strength and become over-vulcanised. This is known as post-vulcani-

sation.

(2) Disaggregation and depolymerisation:

(i) Weak material connections: these are defined as aggregation and disaggregation.

(ii) Chemical degradation action: this is defined as depolymerisation.

(3) Oxidation by oxygen in air: oxygen contributes most to tyre ageing.

(4) The meaning of these terms is further explained with data and figures.

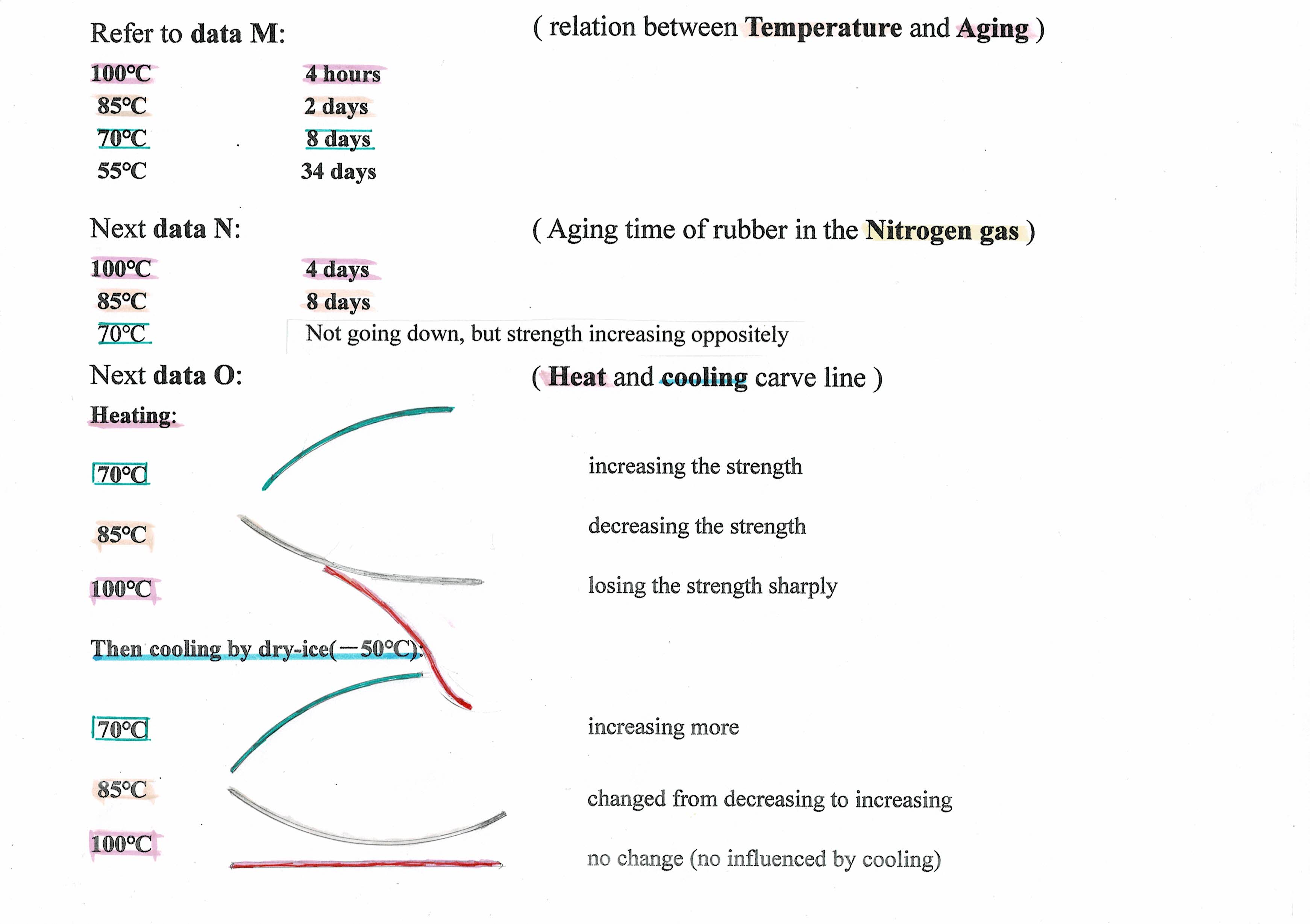

(i) Data M and N show how oxygen promotes ageing.

(ii) what data O indicates:

85 ��C: Weak material connections : aggregation and disaggregation Recoverable.

100��C: Chemical degradation action: �@ depolymerisation �@�@�@�@ Unrecoverable.

�� Once the state of chemical degradation action is changed,�@it is impossible to return to the orig-

inal state. The heat resistance temperature of natural rubber is 80��C and the heat safety tem-

perature is 65 ��C.

3) Properties of natural rubber:

�� Rubber is heat sensitive. Natural rubber:�@�@ the upper limit of the best condition (ambient

temperature)�@ at which its properties remain unchanged over a long period of time is con-

sidered to be 60��C.

4) There are two sides to everything:

Pneumatic tyres have become widely used due to the following features.

(1) Load bearing function (2) Braking and driving function (3) Buffering function (4) Path

keeping function:

However, Path keeping function:�@the friction between the tread rubber and the road surface and

the elasticity of the rubber membrane enable the vehicle to drive steadily even in curves. Friction is

an advantage of rubber, but at the same time it has a disadvantage in terms of heat generation.

The same can be said for air, which has a cushioning function.

C) Physical features of air:

Tyres are made from 'rubber' and 'air'. Their greatest advantage is their light weight.

1) Compressed air is an advantage, also weak point:

The advantage is that it utilises very light air for its shock-absorbing function as a spring. This con-

tributes significantly to tyre weight reduction.

Cushioning function:�@ the elasticity of the compressed air in the tyre and the rubber membrane

acts as a spring to absorb vibrations and impacts �@�@caused by uneven road surfaces encountered

during driving. However, while compressed air is a tyre's strong point, it is also its weak point.

The biggest disadvantage is heat:�@The thermal conductivity of rubber is 0.13, and air is even

worse at 0.0241w/(m�Ek). It's no exaggeration to say that the tyre as a whole is composed of

materials from which little heat is transferred. However, air, as a physical feature, changes in

volume with temperature, and tyre pressure also changes with air volume. This is also a dis-

advantage. since tyre pressure is not stable.

2) Changes in pressure calculated by the Boyle-Charles law:

(1) Boyle's law:�@ V= Vo T/273 Under the same pressure, a fluid (liquid, gas) increases by 1/273

for every 1�� increase in its volume. Therefore, the volume changes from Vo to V.

(2) Charles' law:�@ P = PoT/273 For constant volume, pressure changes from Po to P.

T = absolute temperature (273 + t��C)

(3) Boyle-Charles law: �@ P2 / P1 = T2 / T1 �� P2 = T2 x P1 / T1

(4) �� Tyre pressures should be measured before setting off.�@�@Because tyre temperatures will undoubtedly increase after a ride.

(5) Now let's look at how tyre pressure varies under the following conditions:

(i) Tyre temperature: 25 ��C, Air pressure: set to 900kPa, Tyre temperature: at 90��C,�@what

happens to the tyre pressure?�@The formula, P2= T2 x P1 / T1, with the numbers (273 + 90) x

900 / (273 + 25)=1096.3kPa.

This means that the air pressure has increased by 196.3kPa, or 21.8%up.

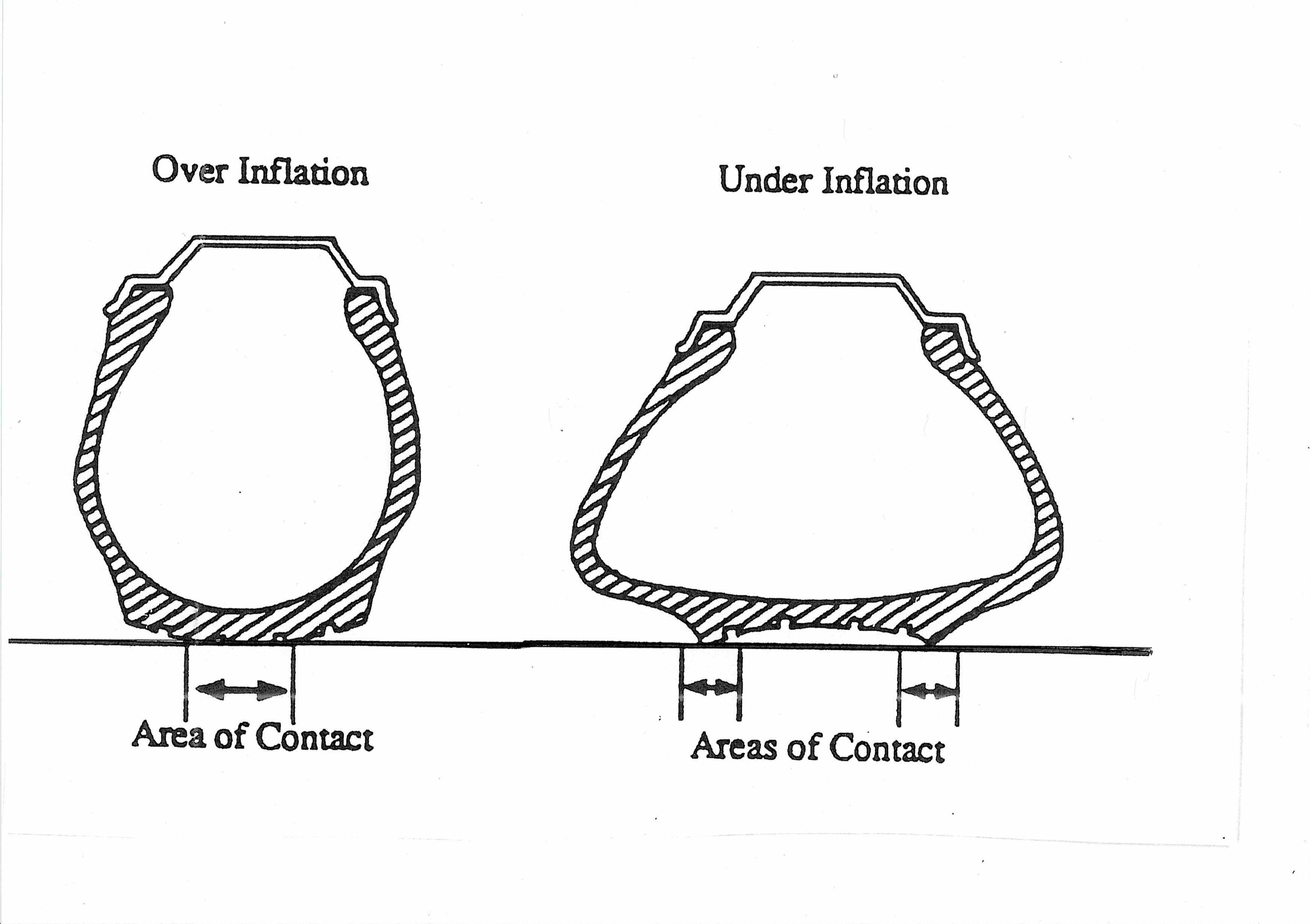

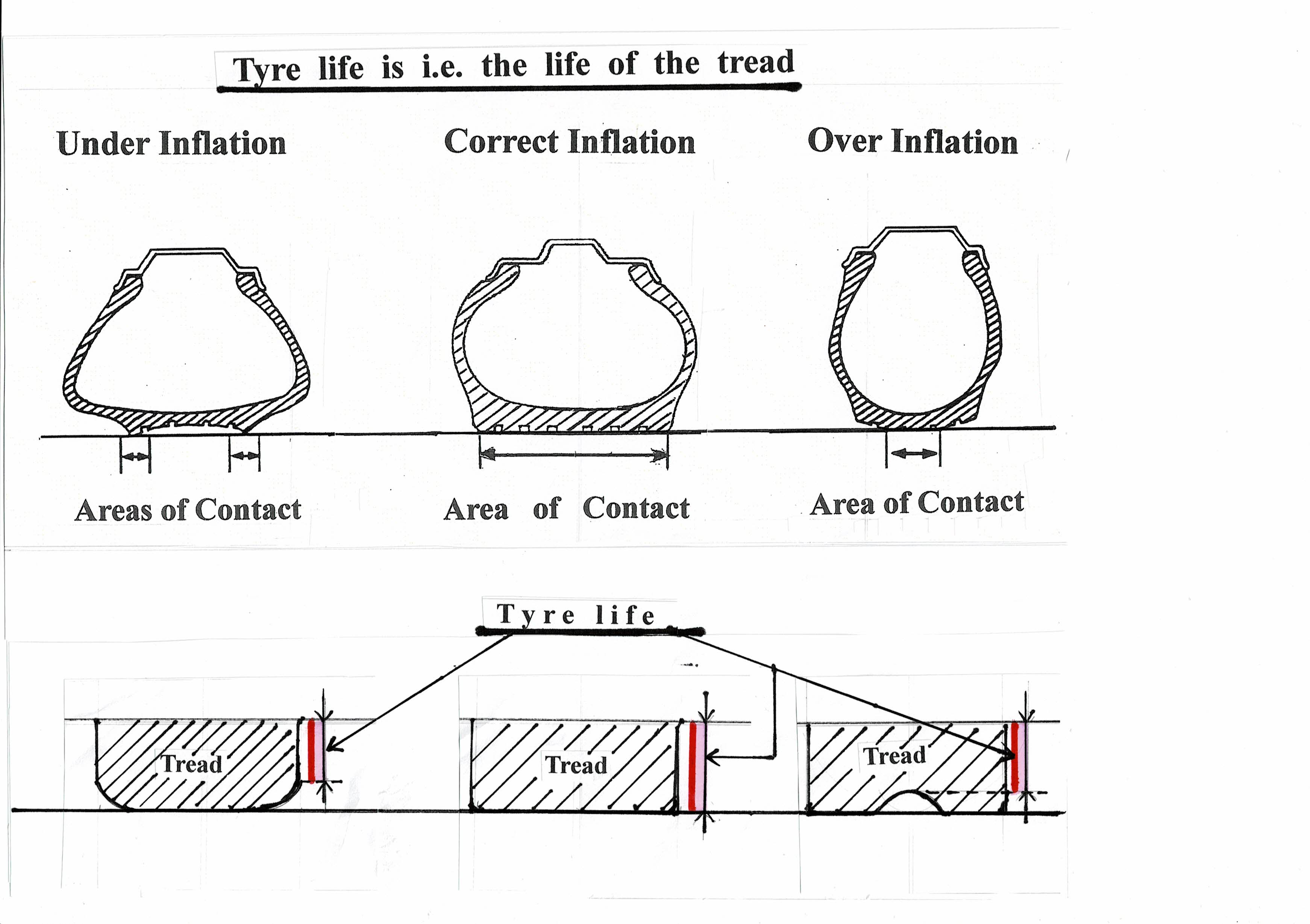

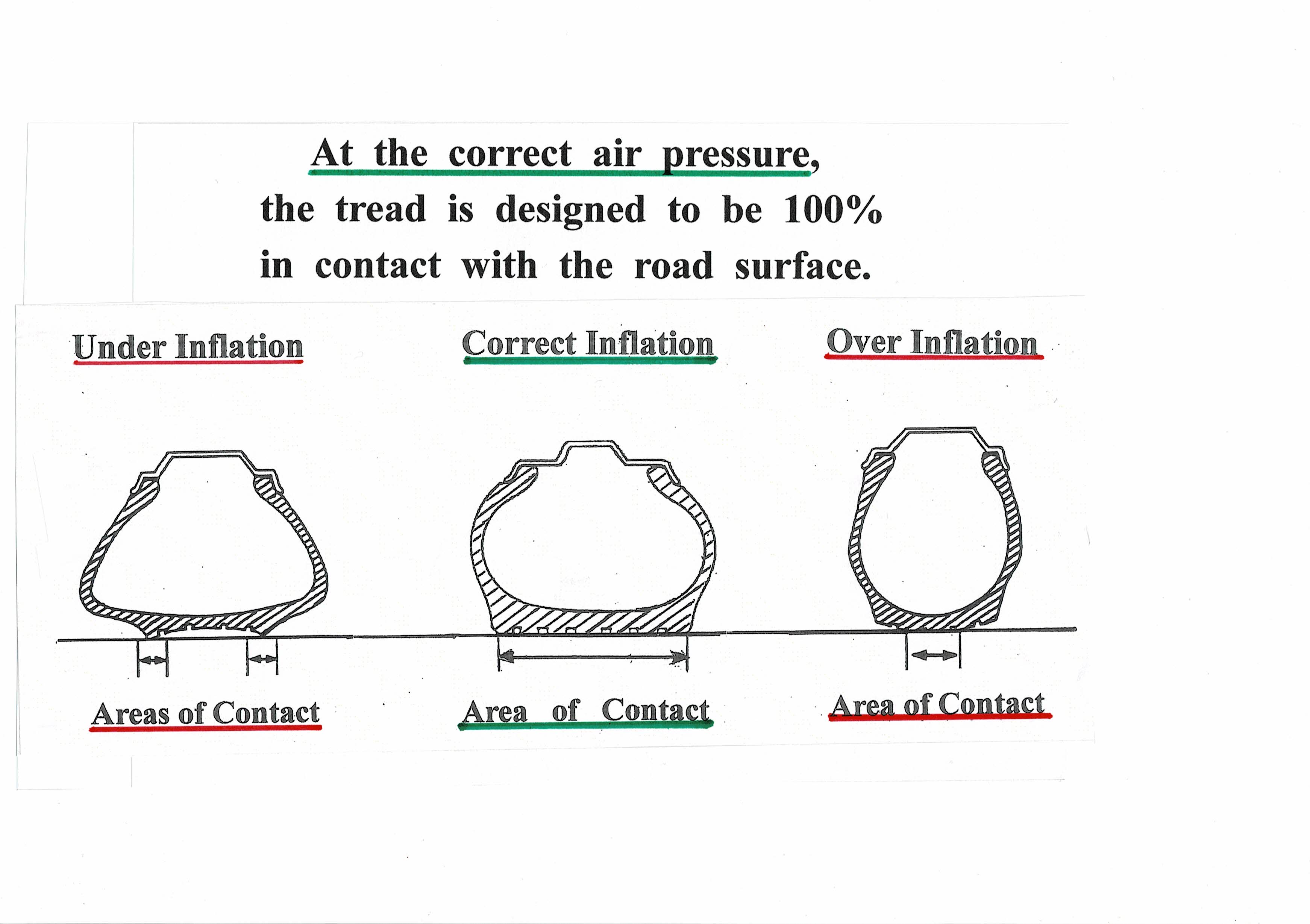

(6) Excess air pressure is pressure that exceeds the range of the correct air pressure:

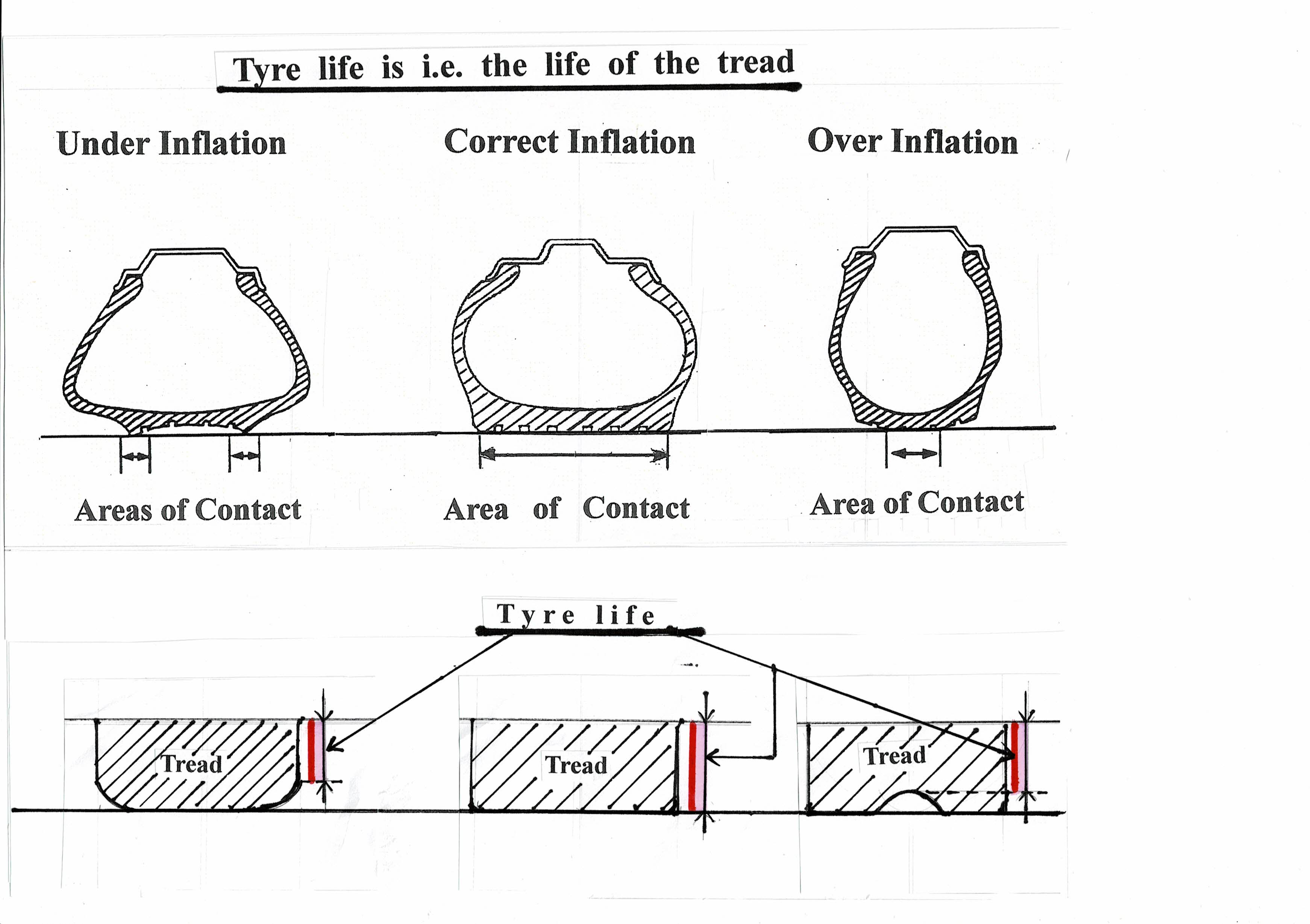

which constantly pulls the tyre rubber hard and weakens the elasticity and strength of the tyre,

causing damage to the tyre. Furthermore, at the correct tyre pressure, the tread is designed

to be 100% in contact with the road surface, and if the air pressure is higher than the correct

pressure, the centre of the tyre will wear, and if the air pressure is lower than the correct pres-

sure, the tyre will wear at both ends, reducing tyre life.

�� Tyre life is, after all, the life of the tread.

See diagram below:

(7) Extreme weather conditions have a significant impact,�@with unusually hot

summers and unusually hot road surfaces,�@which increase tyre temperatures,

which in turn further increases tyre pressure. It is therefore impossible to avoid,

over-inflation problems. Normal tyres operate under such harsh conditions.

D) Why can SELLA achieve 150% tyre life?

Of course, this is possible through good theory. Because reproducibility is science.

Without reproducibility, it can not be called science.�@ Because based on this principle,

this theory, the same results can be achieved by anyone and everyone.�@However,

the people at U.S.Tire-Tech. who first realised this did not understand at all, how the

theory could increase tyre life by 150% over NORMAL tyres.�@�@ They only under-

stood it as a result, not the theory. Therefore, for them, it is only a coincidence.

1) What is SELLA Tyre Service Product?

SELLA TSP is a fibre-containing, viscous, water-soluble chemical.�@ When the vehicle is stationary,

SELLA accumulates at the bottom of the tyre due to gravity. However when the vehicle is moving,

the centrifugal force generated by the rotation of the tyres carries it away. In other words, SELLA

is carried by centrifugal force and covers the inside of the tyre in a thin layer. This thin layer

is the dedicated heat transfer road inside the tyre. In other words, SELLA is carried by centrifu-

gal forces and covers the tyre interior as a thin layer.�@This thin layer is the puncture preventative

product, a layer of evenly dispersed fibres that covers the inside of the tyre due to the centrifu-

gal force of the tyre in order to prevent punctures. However this layer also serves as a dedi-

cated roadway for transferring the heat created inside the tyre.�@ What a coincidence! No,

what luck! This coincidence has given the tyre a life of 150%. In a normal tyre with low ther-

mal conductivity, the heat generated is transferred little by little, slowly and over time.�@ However,

the SELLA heat transfer roadway conducts heat three times better than a tyre, and because

the heat roadway covers the entire inner surface of the tyre,�@�@heat can move freely from

higher to lower temperatures,�@�@ enabling heat generated from the tyre tread to be trans-

ferred quickly to other cooler areas.�@ Then the cooling by forced convection can then cool

the heat efficiently.�@ In other words, the creation of a path for heat transfer inside the tyre.

SELLA cools a large area quickly;�@without SELLA, there is no way to transport heat, even if

there is an area, the heat is not transferred and the area is not cooled, which is normal tyre.

E�jTheoretical, predicted cooling effect:

Let's examine whether SELLA is actually more likely to cool heat than Normal Tyre.

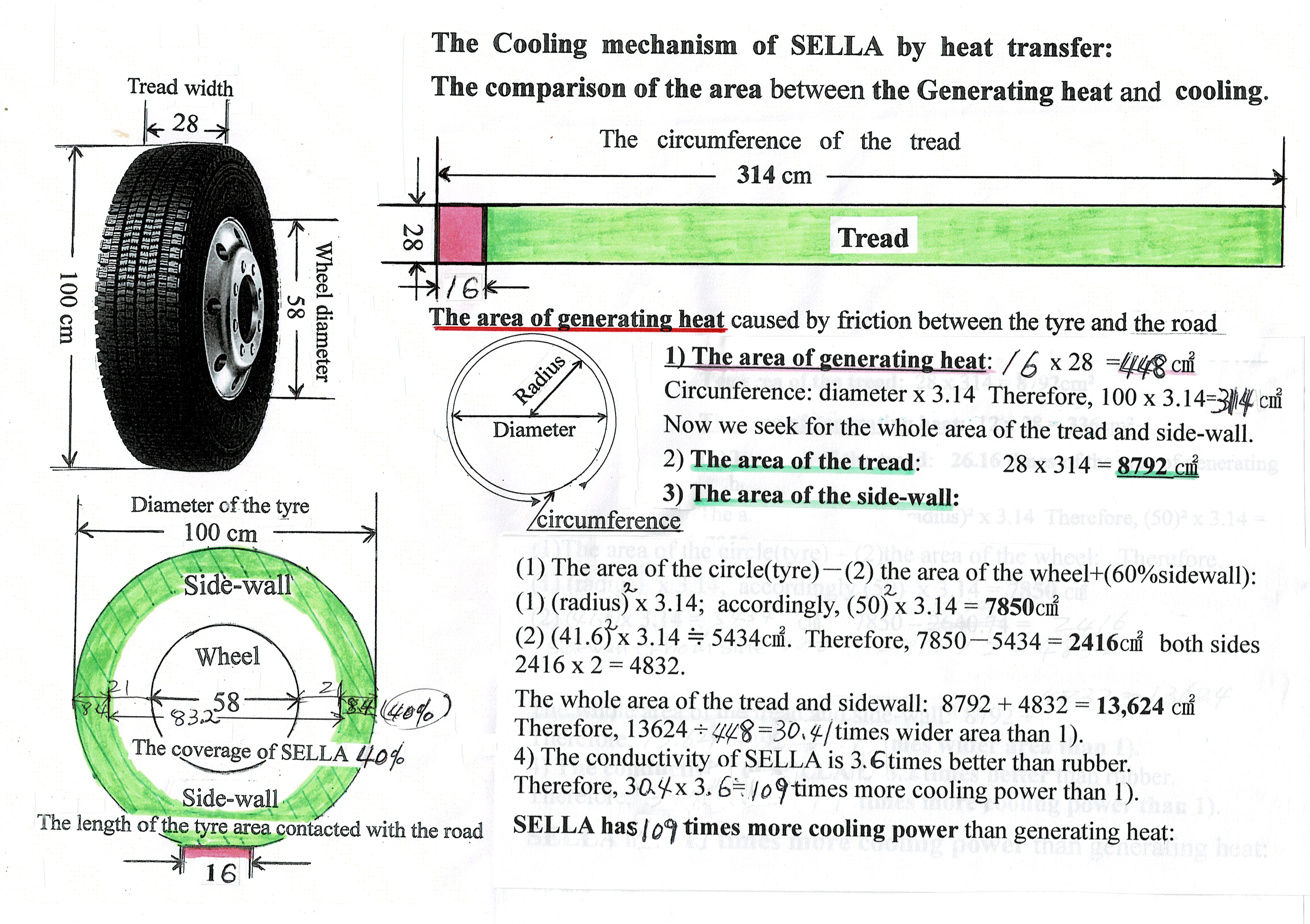

1) Take tyre, 11R22.5 as an example:

Inch units, so correct to a number that is easy to calculate. The result is as follows:

Tyre width: 28 cm, diameter:100 cm, wheel diameter: 58 cm

(1)The area of generating heat:

The distance between the ground contact surfaces of a single tyre tread under the appropriate load

is 14 cm. Then the area that generates heat is 28 x 16 = 448 cm2.

(2)The area of the tread: 28 x 314 = 8792 cm2.

(3)The area of the sidewall:�@ The area of the 40% sidewall can be found by subtracting the

area of the remaining diameter length (8.4 x 2) of the 40% sidewall from the 100 cm diameter.

That is. (1) the area of the tyre circle�@- (2) the area of the wheel + (60% sidewall):

(1)(radius x radius) x ��; (50 x 50) x 3.14 = 7850. (2)(41.6 x 41.6) x 3.14 �� 5434. Therefore,

7850-5434 = 2416. Both sides, 2416 x 2 = 4832. �@ Therefore, the whole area of the tread and

side-wall is; 8792 + 4832 = 13,624.�@ 13,624��448= 30.4

Therefore, the area of the SELLA is 30.4 times larger than the area of generating heat.

(4) The thermal conductivity of SELLA is 3.6 times better than rubber, so 30.4 x 3.6 �� 109.4

i.e. SELLA has 109 times more cooling power.

(5) This is clearly explained in the diagram, please see to it.

In conclusion; compared to Normal tyre.

(1) The cooling area is 30.4 times larger than the heat area:

(2) The COOLING EFFECT is 109 times higher.

F) Scientific proof by data:

1) In what way cooling effect of SELLA be demonstrated?

It was decided to measure and compare the heat calories accumulated in tyres as excess

heat in Normal and SELLA tyres under exactly the same conditions.

(1) The General Motors Research Institute was consulted to determine how much driving, at

full load at least, would be required to obtain data on the heat generated by friction between

the tyre and the road,�@which accumulates as excess heat in the tread area of the tyre, and

was advised that one hour of driving, at full load, would be sufficient.

(2) 27 Aug 1996, 9:a.m, outside temperature 27��C, cloudy.�@ Vehicle: Volvo 20-ton dump

truck (12 wheels).�@ Under the same conditions, SELLA was installed on one of the single

tyres and the other was prepared as a normal tyre in order to obtain data.�@ The load was

20 tonnes, full load, at a speed of 50 km/h for one hour.

Tyre size:12R22.5 with 50 oz/tyre of SELLA.

(3) After driving for one hour, the vehicle was stopped. The temperatures were then measured

for 30 minutes at three pre-marked tyre points: such as (i) tread. (ii) sidewall, and (iii) wheel.

Why did we measure the temperature of the wheel, which was far away from the generated heat?

It was to confirm this, as the manufacturer and even Dupont claimed at the time that the heat

was being dissipated from the wheels. However, I had strong doubts about this idea. I dared to take this data to show what the truth is.

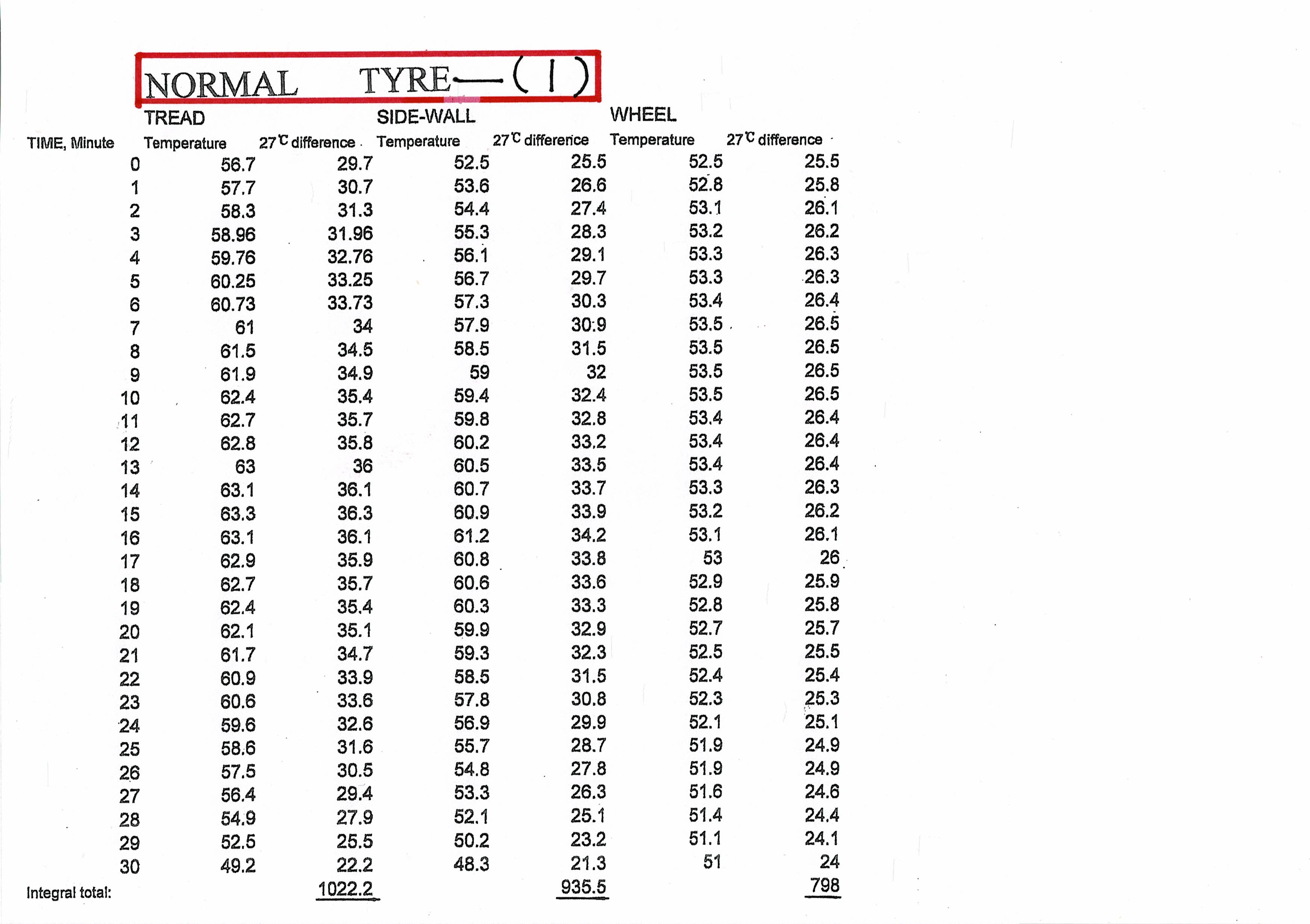

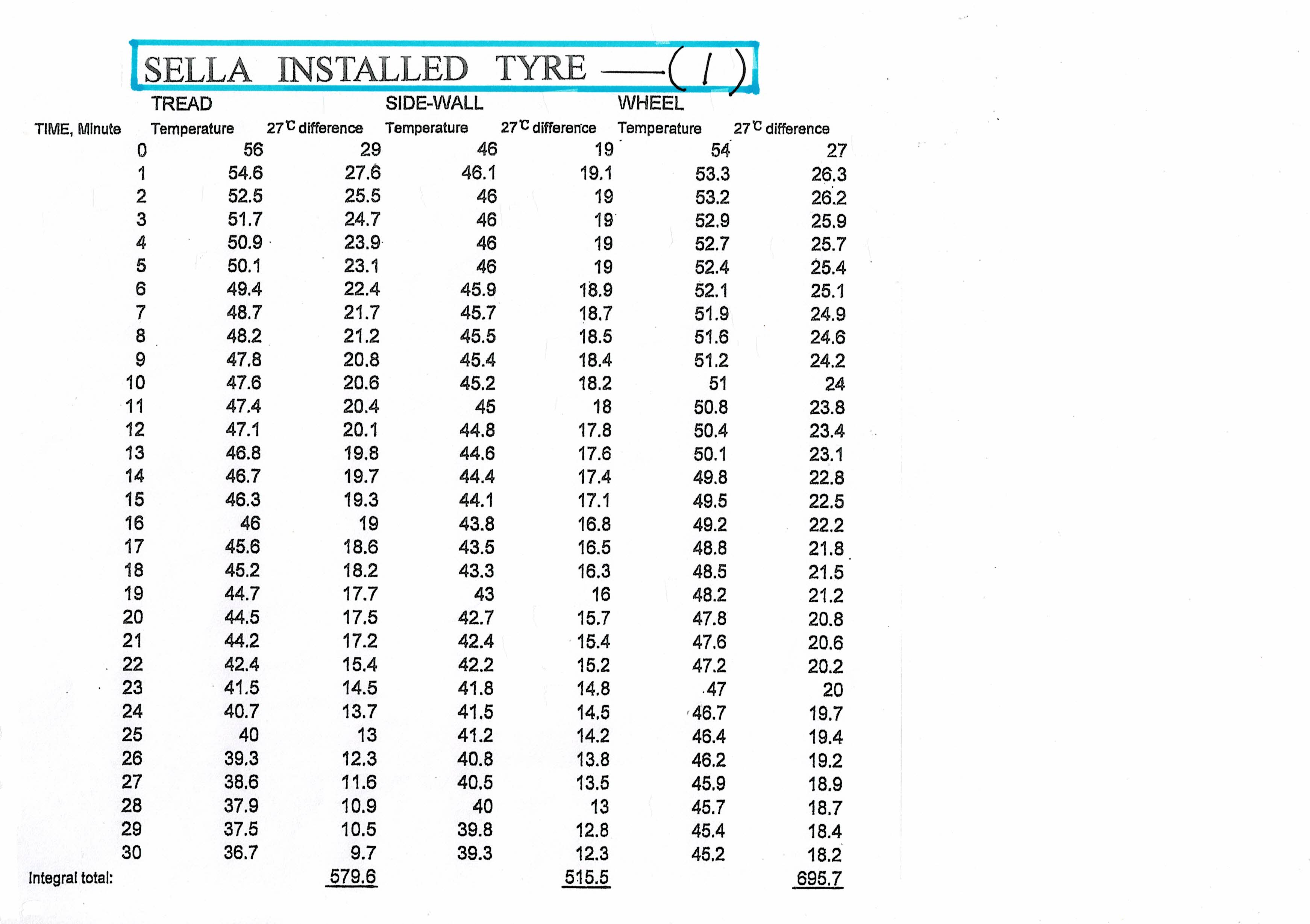

(4) The data are shown here.

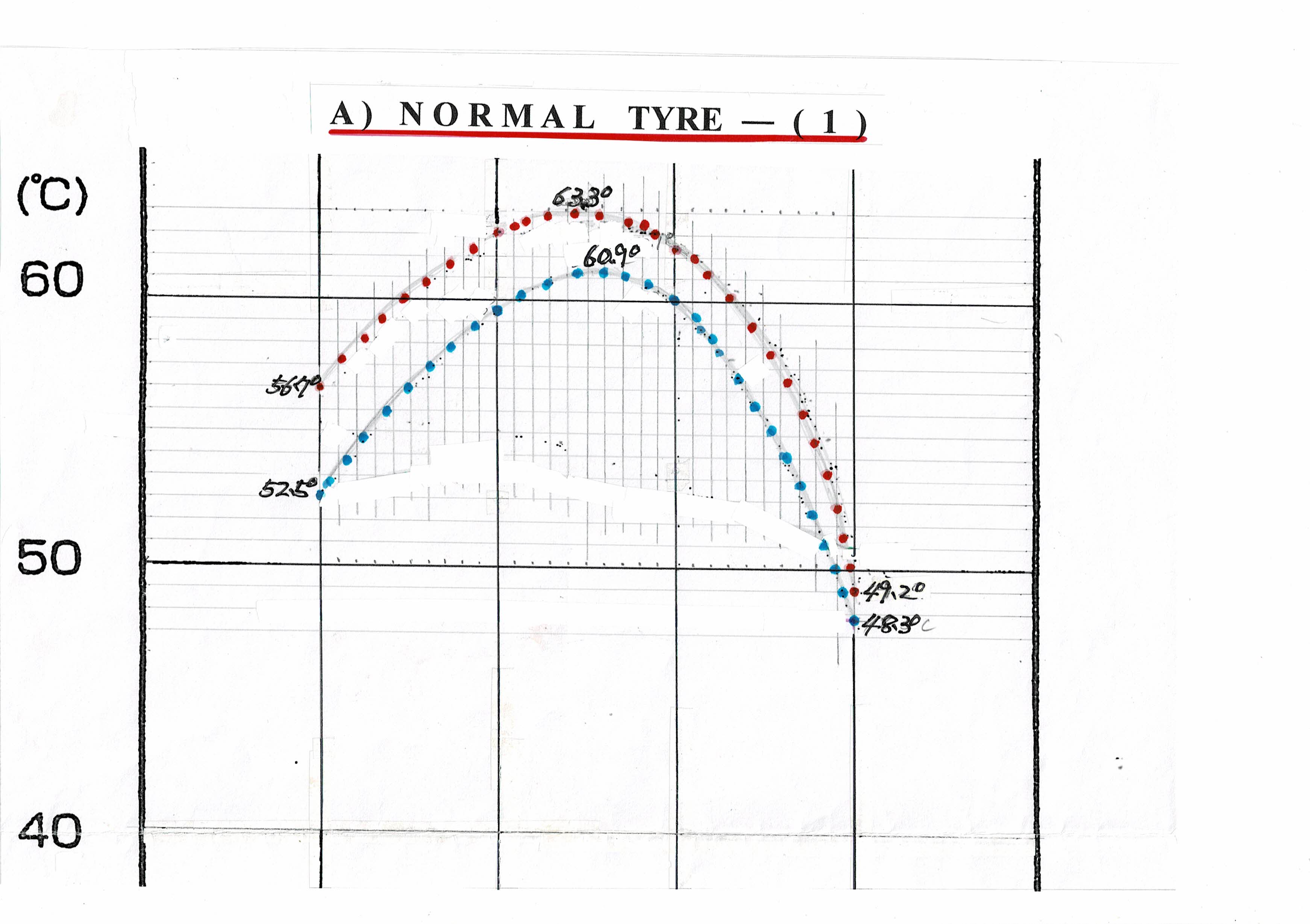

a) �@Data�G�@�@�@ A) NORMAL TYRE-(1)

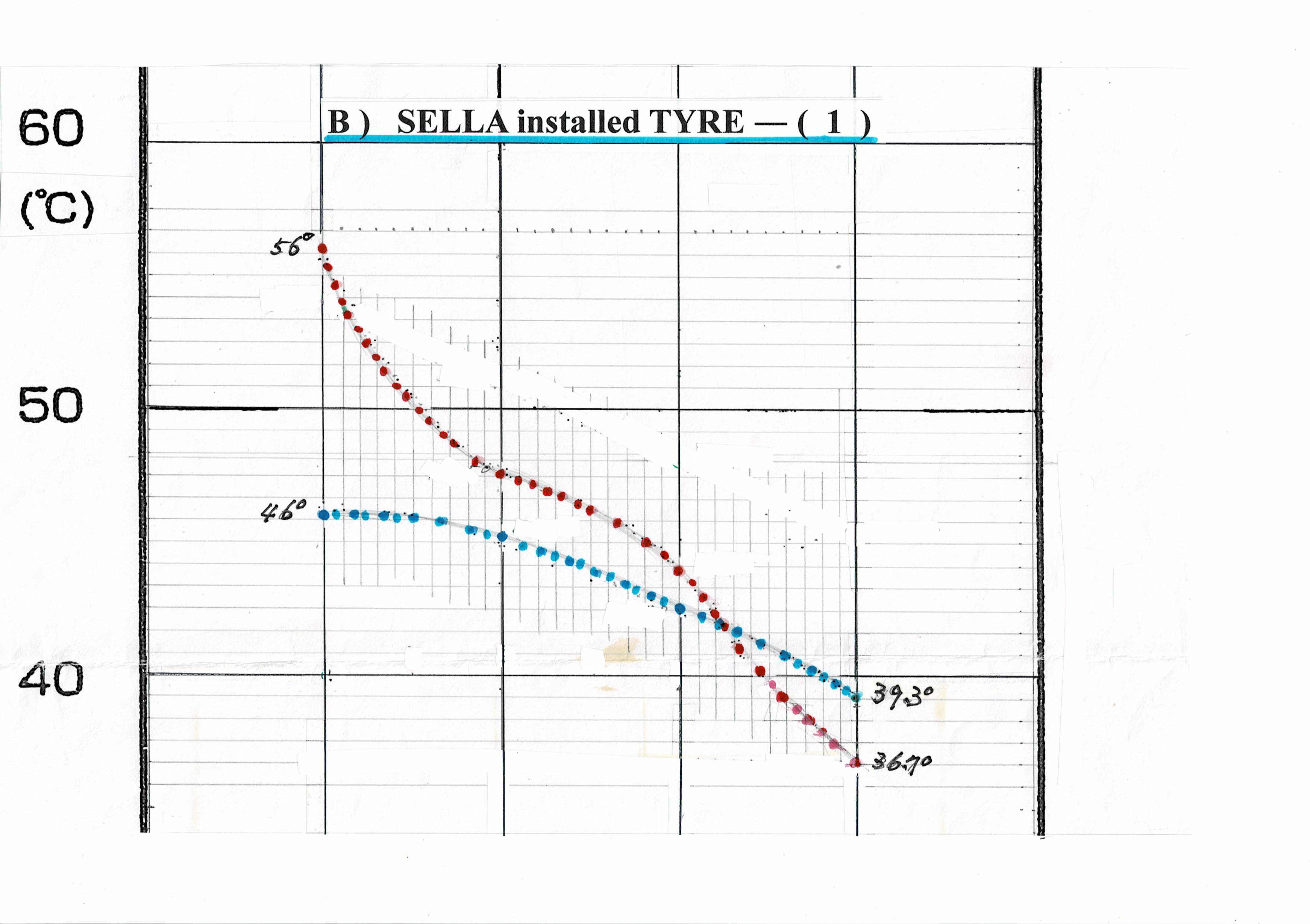

b) Data; B) SELLA installed TYRE-(1)

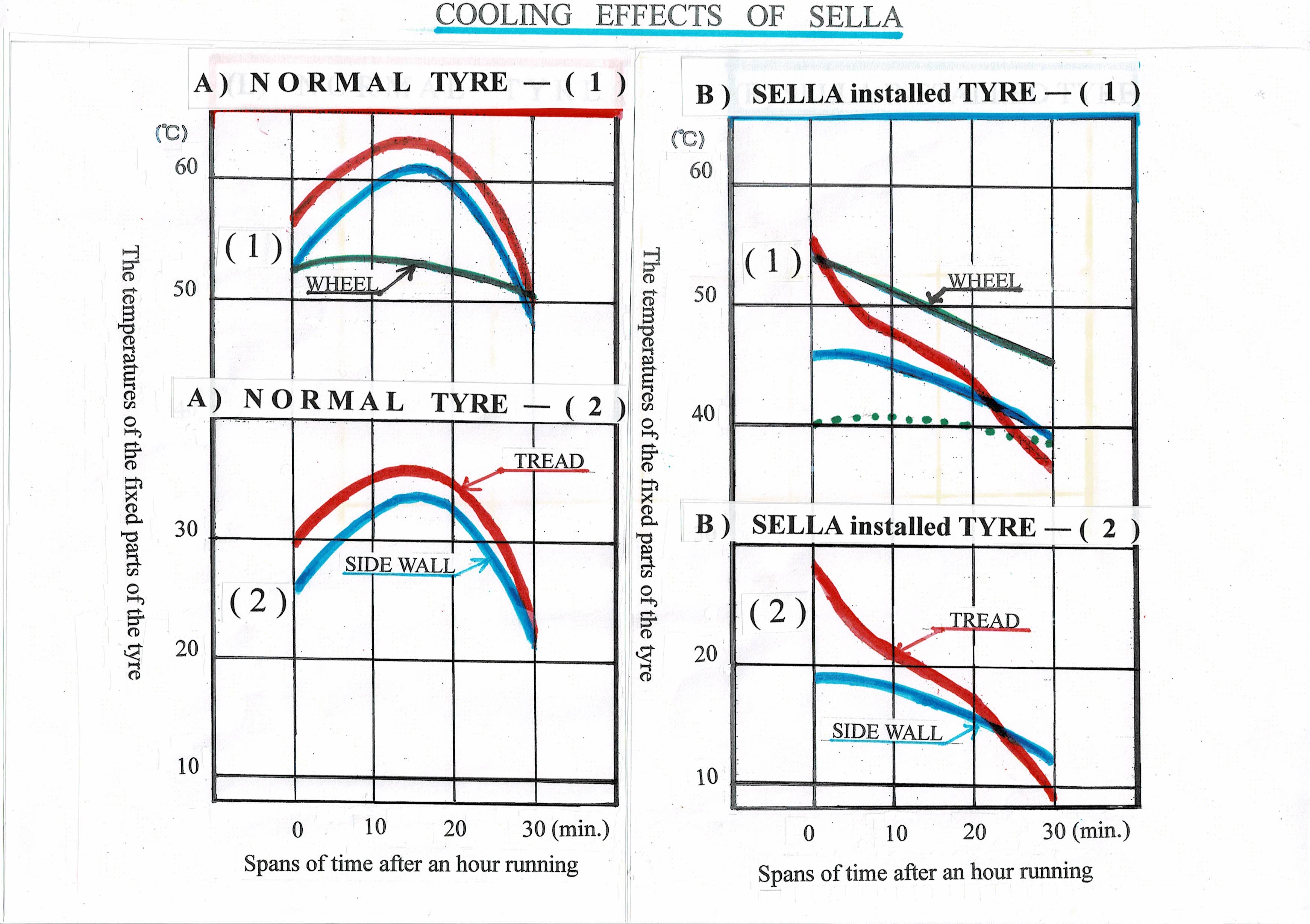

(5)A faithful graphical representation of this data is as follows.

(6) Diagrams created on the basis of the data.

The data should be represented in a diagram so that the characteristics of the data can be

immediately recognised when looking at it. It is this.

2) Data features:

(1) A) NORMAL TYRE-(1):

(i) The diagram based on tyre temperature data shows that the graph is curved, indicating a high

heat dissipation, and it is obvious that a large amount of heat is accumulated as excess heat

in the tread and sidewalls.�@ In contrast, however the wheels, which are metal and have high

thermal conductivity,�@do not accumulate any heat and the graph shows almost a straight

line.

(ii) It can be seen that the amount of heat generated is greater for treads than for sidewalls.

(2) B) SELLA installed TYRE-(1):

(i)The tread, which shows almost the same temperature as the normal tyre due to heat generated

between the tyre and the road surface until just before stopping, even though the tyre is receiv-

ing the cooling effect of the SELLA, is clearly placed at a disadvantage in terms of heat gen-

eration when compared with the sidewalls.�@However the graph shows a sharp, steadily de-

creasing trend,�@and it is clear from this figure that no excess heat is accumulated in the tread

area, which is the heat source.

(ii)The sidewalls do not fall down the graph as much as the tread,�@ partly because they are not

the main source of heat. This means that the degree of temperature change is less.

(3) Misleading data:

a) B) SELLA installed TYRE-(1): This data is misleading to people.

Where does the data become misleading? It is the position of the wheel. The temperature is

higher than the tread, which is where the heat is generated, and the sidewall next to it. The

diagram must give the illusion that the heat is being dissipated from the wheels. Thus it is da-

ta that misleads people.�@Of course, this is data, it definitely represents facts. What facts does

it represent?�@ It states that SELLA covers 40% of the sidewall of the tyre and "SELLA never

reaches the wheel"�@But forgetting this leads to a world of complete delusion.�@ In other words,

why is the wheel position's temperature higher than the tread,�@ which is the heat source?

Such a thing is scientifically impossible.�@ However the fact is that the data speaks for itself:

people who are unaware of the fact that SELLA does not reach the wheel will completely be-

lieve this data. Therefore we have to say that the data is to be misleading to people. For refer-

ence, what would happen if SELLA had reached the wheel?

It is shown in B) SELLA installed TYRE-(1), below the diagram, a single dotted line is shown.

It is completely below the tread and sidewall.�@�@Therefore it would be appreciated if you could

understand that even the wheel at the bottom of the A) NORMAL TYRE-(1) diagram, would be a-

bove the tread if the cooling effect is small as shown in B) SELLA TYRE-(1) diagram,�@when

the SELLA does not reach the wheel.�@�@ Where there is no SELLA, there is no heat transfer

roadway, so heat cannot be moved effectively.

b) Neither U.S. TIRE-TECH INC. nor U.S. DUPONT are aware of this theory:

But, I am by nature a man of ideas who cannot accept anything that goes against scientific

principles and scientific facts.�@�@So, I was driven by a strong desire to show that the 150%

tyre life expectancy is reproducible, caused by scientific principles. And I wanted to find out

by the scientific method. And I was led to this method.�@However the data from the wheel is

essentially irrelevant to SELLA.�@�@�@The reason for this confusion may be that I had in mind the

claims of U.S. TIRE-TECH and U.S. DUPONT that heat is ultimately dissipated from the wheels,

and I took the wheel data for that purpose.�@�@ The reason is that SELLA data was mixed in

with the data of wheels that were not subject to the cooling effect of SELLA.�@ I must apolo-

gize for this. Therefore, the wheel data shall be excluded. It's the diagram A) NORMAL TYRE-(2)

and B) SELLA TYRE-(2).

3) Comparison of data through rigorous analysis:

With this data,�@ the heat release calories from each part of the tyre should be calculated to

show the cooling effect in real figures.

(1) To determine the actual heat calories:

The difference between the minute-by-minute temperature of each part of the tyre�@ and the out-

door temperature of 27��C at which the data was run needs to be determined.�@ The difference

between the tyre temperature minus the outdoor temperature of 27��, is the figure needed

to compare the cooling effect. The following integral values were then obtained.

Measuring point:�@�@�@�@�@�@ Normal tyre�@�@�@�@�@�@ SELLA tyre

Tread:�@�@�@�@�@ �@ �@�@�@�@�@1022.2�@�@�@�@�@�@�@�@�@ 579.6

Difference:�@�@�@�@�@�@�@�@ �@442.6 �@�@�@�@ �@�@�@�@ �@43.29% down

Sidewalls:�@�@�@ �@�@�@�@�@�@ 935.5 �@�@�@�@�@�@�@�@�@ �@515.5

Difference: �@�@ �@ �@�@�@�@ �@420 �@�@�@�@�@�@�@ �@�@�@ 44.89% down

Reference.

Wheel: �@�@�@ �@�@798�@�@�@�@ �@�@�@�@�@�@�@695.7

Difference: �@�@ �@�@ �@�@�@ �@102.3�@�@�@ �@ �@�@�@�@�@ 12.81% down

(2) CONCLUSION:�@ The results of this data speak for them-

selves.

(i) Tread: As the main heat source, it certainly has about 8.5% more heat calories than the side-

walls. However, it shows a higher cooling effect compared to normal tyre by 43.29%.

This is a remarkable effect.�@The amount of SELLA is highest in the tread area, which is also

considered to have a significant effect.

(ii) Sidewalls: Next to the tread, they are also a source of heat, although to a lesser extent than

the tread, due to the hysteresis loss heat generated by tyre deformation during driving. Un-

der these conditions, the cooling effect is 44.89% compared to a normal tyre. To put it bluntly,

the cooling effect is increased to half of the normal tyre heat value.

(iii)The effect of the wheels was also investigated,�@�@ but it has already been pointed out that

SELLA does not reach the wheels, so no significant effect can be expected.�@ However, as the

tyre temperature is lower due to the cooling effect of the SELLA,�@ the effect shows only 12.81%

cooling effect. Further, this data proves that U.S.Tire-Tech. and DUPONT's claim that heat is

dissipated from the wheel is completely false. It shows that "heat in the tread area is cooled

in the tread area" and "heat in the sidewall area is cooled in the sidewall area".�@�@ This fact

was also found from this data by the change in the total heat value.

4) Testimony on data relating to SELLA in-

stalled Tyre:

If, under the same conditions, one of the two sets of data obtained is acceptable,

the other is likewise acceptable, even if it is beyond his knowledge.�@ That is the

true scientist.

�@�@�@�@�@�@ �@�@ Technical Adviser �@�@�@Teijiro Wakatsuki

G) The effect of SELLA's cooling capacity:

To examine, on the basis of scientific data, how the cooling capacity of SELLA

affects rubber and air respectively.

�P�j Influence on rubber:

The great invention, by Goodyear, was the vulcanisation process for rubber.�@�@The vul-

canisation process gave rubber its excellent strength and elasticity. However, the

biggest drawback of vulcanised rubber is ageing. What is ageing? It is the loss of

elasticity and strength.�@ Three reasons for ageing, one of which is disaggregation and depolymerisation.

(i) Weak material connections: these are defined as aggregation and disaggregation.

In this state, recovery to the original state is possible on cooling. This state is reached at 85��.

However, in SELLA tyre, 85 x 0.5671 = 48.20, i.e. around 48��C.

(ii) Chemical degradation action: this is defined as depolymerisation.

Once this state is reached,�@it is impossible to recover to the original state, even with cooling.

This state is reached at 100��C.�@ But, in the SELLA tyre, 100 x 0.5671=56.71,�@ 57��.

�� Rubber is heat sensitive:�@Truck tyres are made of natural rubber due to their strength.

Natural rubber:�@�@the upper limit of the best condition (ambient temperature) at which its

properties remain unchanged over a long period of time is considered to be 60��C.�@�@Whereas

normal tyres can reach dangerous temperatures of 85��C and even 100��C, but, SELLA tyres

do not reach 60��C,�@ protecting the tyre from ageing and maintaining its strength and elas-

ticity.

2) Influence on air pressure:

Air increases in volume with increasing temperature. Therefore, the air trapped in the vessel

called a tyre changes in pressure according to the law of Boyle-Charles as we have already learnt;

(i) Tyre temperature:

25�� Air pressure: set to 850 kp: Tyre temperature: at 100��, what will the tyre pressure be?

The answer is 1063.9 kp. This means that tyre pressure is 213.9 kp higher or 25.16% higher.

Tyre manufacturers have defined the adjustment range for filling pressure as 0 to +80 kPa for

truck and bus tyres.�@�@ Thus, in the case of 850kPa, up to 930 kPa is permitted. In this case,

according to the Boyle-Charles law formula,�@�@�@�@�@(273 +100) x 930 /(273+ 25) = 1164kPa,

1164 - 850 = 314 kPa / 850 = 0.369, i.e. 36.9% higher than the correct inflation pressure,

which will add to the tyre overpressurisation.

But what happens with SELLA tyre?

Note:�@�@�@The temperature at inflation pressure setting 25��C remains the same. This is because

the tyre does not generate any heat before driving, nor does SELLA have any cooling effect,

and the tyre is under the influence of the ambient air temperature. The temperature affect-

ed by SELLA is after driving. 100 x 0.5671 = 56.71, 56.7��.�@�@�@�@�@�@�@�@�@�@�@ Therefore,

(273 + 56.71) x 850 / (273 + 25) = 940.4 i.e. �@�@�@�@�@940.4 kPa, an increase of 90.4 kPa.

This is 90.4��850= 0.1063,�@ an increase of 10.63%.�@�@�@�@ Compared to the Normal tyre's

213.9 kPa�� 90.4 = 2.36, this shows an increase in air pressure of 2.36 times that of SELLA

tyre.�@ �@ In case of the full air pressure adjustment range of +80kPa., 314kPa��90.4=3.47.

In this case, 3.47times higher air pressure than SELLA tyres.

In contrast, SELLA can enable cooler running of the tyre. It contributes to reducing exces-

sive heat generation and stabilising air pressure. Tyre life depends on maintaining the cor-

rect inflation pressure,�@�@and tyres that are over-inflated or under-inflated have less tread

contact with the road surface, making it difficult to wear the tread evenly and reducing tyre life.

The ground contact area of under-inflated and over-inflated tyres is smaller than the ground

contact area of correctly inflated tyres.�@ Therefore as the load is the same, the load per ground

contact area is greater, resulting in greater tyre wear.

See again the diagram below.

H) Summary of what we have done so far:

Why can SELLA, achieve 150% tyre life?

The answer to this question is as follows:

Why is SELLA TSP able to achieve 150% Tyre Life?�@This is based on the assumption that it

is a comparison under the same conditions as normal tyre. First, let me clarify the meaning of

the word. How did this technology come about? This technology was discovered by accident

by US Tire-Tech Inc.�@�@ If they had looked at the scientific reasons why tyre life has increased by

more than 150%, the situation might have been different. However they did not try to find out why

for what reason, or theory, the life of the tyres increased significantly. At least, they weren't people

with that kind of scientific thinking. However, having made such a great discovery, albeit by chance

they naturally asked a transport company called Conoco Fleet�@ to collect driving data for 5

years from 1990 ~ 1995 in order to sell products made by their technology.�@�@ And all the

driving data over the past five years proved that the product definitely has a longer lifespan

of more than 50% compared to normal tyres.�@�@Dupont showed great interest in this data.

Dupont supplied them with a special fiber called Kevlar. Dupont then decided to sell the product

to the global market.�@ The samples were then sent to the European market. However, some-

thing unexpected happened. It was a problem of rust on the wheels. At that time, even now,

there is no technology in the world to prevent rust on wheels.�@�@Dupont, the world's largest

chemical company, is understandably aware of the problem.�@�@Therefore, they had no choice

but to withdraw from this business. Of course, the manufacturer, US Tire-Tech Inc., is also in-

cluded. Therefore, this information is known only to a very limited number of companies in-

volved in this product.�@ I came to know this product by accident as someone who worked for a

very short period of time as a Sole Agent in the Asian territory.�@�@ And the manufacturer, US Tire-

Tech, and Dupont, the world's largest chemical company, have all exited the business. However

as a development company,�@I was not disappointed to see this excellent technology disap-

pear from this world,�@and I was determined to take on the challenge of developing a com-

plete product. �@I have mainly worked in the electrical industry such as communication equipment

and small-scale machinery, and this is my first time working in the chemical field. It's a conun-

drum that even Dupont, the world's largest chemical company, gives up.�@�@ I had no hesitation?

If I said there wasn't, I'd be lying.�@�@�@ However, I was struggling with the business due to the

strong yen, I was prepared to suffer from some problems.�@ I had tasted a lot of the harshness

and bitterness of the world, and I knew that the world was not so sweet. As a development com-

pany,�@�@ I am looking for products that do not get involved in price competition, give great

benefits to users, and contribute to the prosperity of users. If the product has the potential

to meet this purpose, be prepared for some difficulties. What further encouraged me was the

fact that the effect of the product was already clear. Normally, our role in development is to

create products that the market and customers want.�@�@It is our job to decide what means

and methods we will use to achieve that goal. However, this time, we don't know what kind

of mechanism it is, but we know the result (target) of increasing tyre life to 150% or more

in advance. �@ The development of a product strives to achieve its objectives, but in this case, it is

not clear why this is so,�@ but the result of Tyre life 150% is already evident in the test data

over 5 years, and this fact is undeniable.�@ And without this fact, I would not have taken on

the challenge of developing this project.�@ Because if you ask me to develop a product that

makes 150% Tyre life possible, I can't think of a way to do it completely.�@�@If I can't find a

solution in my head, I can't develop it. Thus, this is the end of the matter. However if the prod-

uct can already promise results that can guarantee more than 150% of Tyre life,�@ that is a

different story.�@�@We don't know the cause, but if there are results, comparing Normal tyre

and SELLA TSP to find out the cause, the reason will naturally become clear. It is something

that can be done without an idea.�@�@ Therefore, it is the work of the lazy to refuse it. Of course,

it is not easy to theorize, but there is always a way.

1) SELLA Tyre Service Product:

A fibre-containing, viscous, water-soluble chemical.�@�@ When the vehicle is driven, the centrifugal

force generated by the rotation of the tyre carries SELLA away and covers the inside of the tyre in

a thin layer. This thin layer was also a dedicated heat transfer road created inside the tyre. As

the dedicated heat transfer road conducts heat three times better than the tyre,�@and as the

dedicated heat road covers the entire inner surface of the tyre, heat can move freely from hotter

to cooler areas,�@�@enabling heat generated from the tyre tread to be quickly transferred to

other cooler areas. The heat can then be efficiently cooled by forced convection cooling.

2) How effective is cooling by SELLA?

The vehicle is driven under the same conditions, tyre heat data is taken and compared with

normal tyre. The results were;

(1) Tread: 43.29% down �@(2) Sidewall: 44.89% down.

The cooling capacity of SELLA has a significant impact on the tyre, �@which is composed of

rubber and air.

3) Critical temperatures against ageing:

which is the greatest drawback of vulcanised rubber. That is over 85�� and 100��.

But, if SELLA served:�@85 x 0.5671 = 48.20��C. 100 x 0.5671 = 56.71��C.�@ All are

below 60��C.

Natural rubber is heat sensitive, and the upper limit of the best condition(ambient temper-

ature) at which its properties remain unchanged over a long period of time is 60��C.

SELLA provides cooling capacity and keeps the tyre temperature below 60��C, protecting it

from ageing and maintaining the strength and elasticity of the tyre.

4) The cooling capacity, keeping the tyre pressure:

SELLA protects the tyre from over-inflation, keeping the tyre pressure within regulation

and helping to ensure that the tyre tread maintains 100% of the ground contact surface.

Tyre life is the life of the tread, and how well the tread maintains 100% relative to the

ground contact surface is a key factor in tyre life. The tyre life is the life of the tread and

how the tread maintains 100% contact with the ground surface is very important for the

life of the tyre. However for excess pressure, Normal tyre does not know how to respond to

this. So far the main focus has been on how SELLA was able to use its cooling capacity to

deal successfully with the problems caused by excess heat in the tyre. In other words, the

main explanation is how SELLA was able to cope with excess pressure. If the life of a tyre is

defined as the life of the tread, and 100% contact of the tread with the ground surface is re-

quired at all times, then one important point is missing. That is the problem of under-infla-

tion. If this cannot be addressed, it cannot be said to be complete.

I) SELLA solve the insufficient air pressure:

1) the primary enemy of tyre life and the tyre failure:

Tyre life decreases sharply as under inflation increases.

See the diagram below.

2) The problems caused by insufficient air pressure?

Under-inflation below the specified pressure, affects tyres and vehicles in several ways.

(i) Accelerate wear at both ends of the tread, reducing the life of the tyre.

(ii) It can lead to rim bruises and rupture.

(iii)It causes increased tyre flexing which leads to tyre cord breakage, break down of the bonding between the

rubber, the body fabric and the steel belts.

(iiii)Increased rolling resistance of the tyres and increases fuel consumption.

3) What causes the loss of air pressure?

Typical examples are punctures,�@�@but others, such as periods of vehicle nonuse, tyre rim

leaks, and bead leaks.

Rubber tyres are relatively porous and a fully inflated tyre at rest for a period of time will lose

air pressure.

Let us now see by what means these problems are being addressed:

SELLA uses special chemicals to deal with pores in the tyre material. To achieve 100% tyre

life required by tyre manufacturers, other puncture holes and gap leaks are also addressed.

J) Features against punctures and air leaks.

Tyres become under-inflated when they lose air due to punctures or other causes.�@The de-

gree of under-inflation has a significant impact on the tyre life, so the first requirement for

this product is to minimise the loss of air pressure from the onset of a puncture.

So how does SELLA respond to these problems?

1) SELLA sealing mechanism:

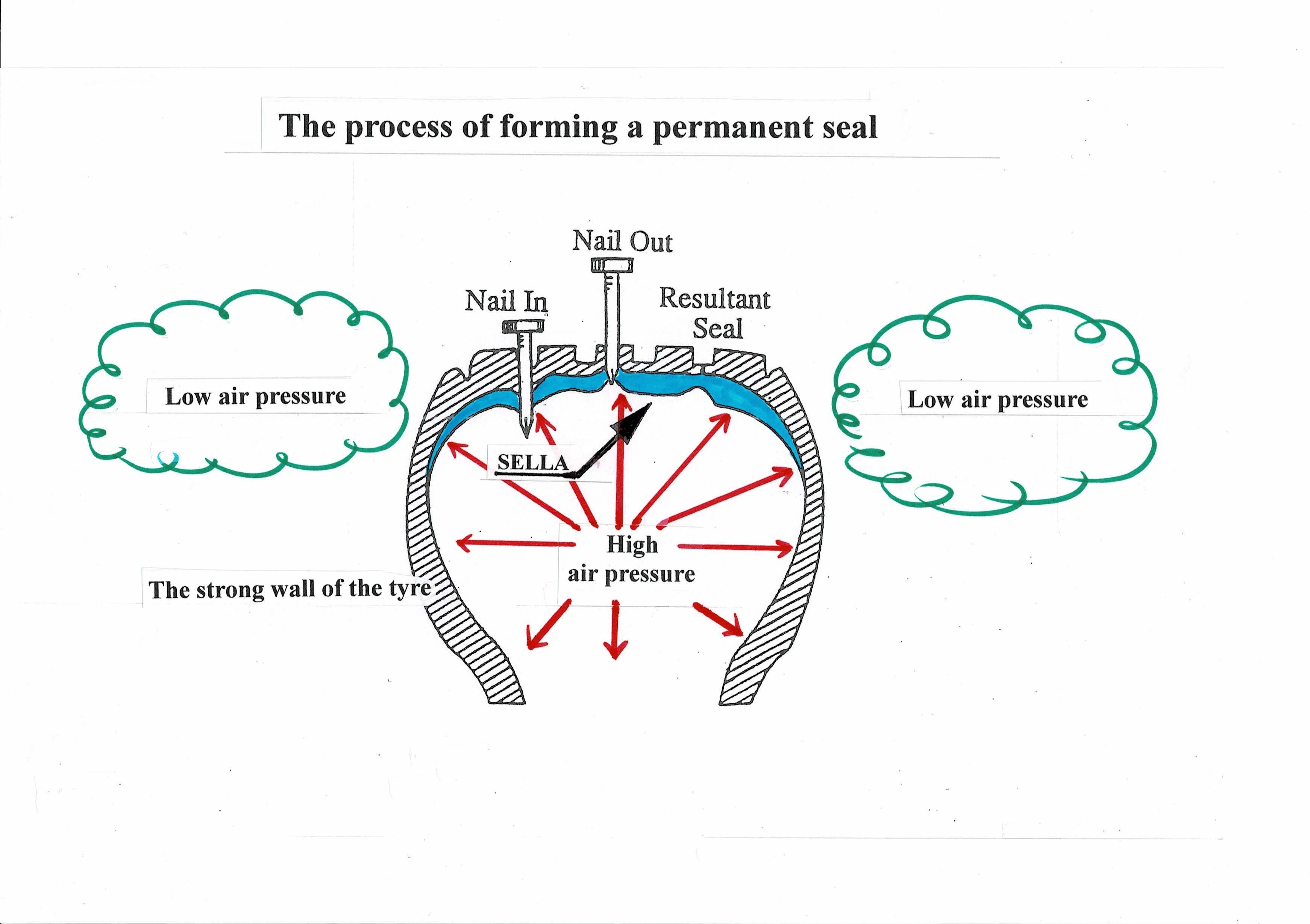

"Air moves from a point of higher pressure to a point of lower pressure"

Sealing by SELLA applies this principle and it is the elasticity of rubber. What is the elasticity

of rubber?�@Rubber deforms when an external force is applied. However, when external forces

are removed, the rubber returns to its original shape. This is the elasticity of rubber.

What is the condition of the inside of the tyre during driving? The centrifugal force generat-

ed by the high-speed rotation of the tyre causes SELLA TSP to carry the tread part to the main

and to the part of the sidewall. SELLA TSP is then attached to the inside of the tyre in a thin

layer. Due to centrifugal force, SELLA TSP, which sticks to the surface of the inside of the tyre

in a thin layer, is at the same time pressed by the high pressure inside the tyre.�@ The pres-

sure gap between the inside the high-pressure tyre�@�@ and the outside of the low-pressure

tyre is equilibrated by a strong wall of the tyre.�@ But what happens if a foreign object such

as a nail penetrates the wall of the tyre?�@As already mentioned, air moves from high pres-

sure to low pressure. Truck tyre pressure is very high. Therefore, the energy of air to move

is also large. When a foreign object breaks the tyre, a puncture occurs. At that time, SELLA,

which is in a state where the fibers are evenly dispersed,�@�@ which is attached to the tread

surface of the tyre in a thin layer, is pushed by high-pressure air with a large amount of en-

ergy and moves out of the tyre through the puncture hole. Then instantly sealing them and

preventing air leaks due to the elasticity of rubber. �@This is an essential technology for tyre

life and can also be referred to as SELLA's 'auto-repair' function,�@which prevents under-in-

flation.

2) The process of forming a permanent seal�F

When a puncture occurs, SELLA surrounds the puncturing object such as nails,etc to prevent

pressure loss.�@�@�@When the puncturing object is removed, fibres are forced into the puncture

forming a permanent seal. The sealing is accomplished through the combination of:

(i)centrifugal force(rotation); which forces SELLA out to the tread area;

(ii)air pressure; which forces the SELLA fibres into the puncture hole; Even if the fiber enters

the hole, it will not seal if it is not elastic.

(iii)vehicle weight;�@�@�@ which constantly flexes the tyre as it rotates and works the fibres

densely into the puncture hole.

This sealing process allows a minimal loss of air pressure and results in a cured plug that is

impervious to water, mud and snow.�@It shows the mechanism of sealing by SELLA and the

process of forming a permanent seal.

Needless to say, this great invention was made by the Americans as a puncture preventative

product. And this technology has enabled a 150% tyre life. But this great invention was about

to disappear from the world due to wheel rusting problems:

Why did Dupont,�@the world's largest chemical company, give up on this product because of

wheel rusting problems alone? For what we do not understand, even if it is excellent in the eyes

of others, it is but a tower on the sand.�@Without understanding, there can be no great power to

move people towards solutions to their problems.�@�@ This is why I did not start by solving the only

problem with this product - wheelrust -�@but, began my research by clarifying the 150% tyre life

already revealed by five years of running data. I have spent lots of money and time to this end.

As a result,�@�@ it became clear that, beyond the original developers'intentions, if the product

could be made so that centrifugal forces, generated by high speeds,�@did not cause separa-

tion,�@�@�@and if it could cope with wheel rust caused by the replacement of tube tyres with

tubeless tyres, it would certainly be possible to achieve a tyre life of 150%.

The history of a puncture preventative product products to date suggests�@ that they were not de-

veloped by the will of man, but were a gift from heaven. This is because no one thought to

develop a product with 150% tyre life from the beginning.�@Therefore, it can only be consid-

ered a gift from heaven.�@ The secret of 150% tyre life is the commitment to Correct Infla-

tion. Tyre life is the tread life. The tread is designed to make 100% contact with the ground

surface at the correct inflation pressure.

3) Under-inflation is the primary enemy of tyre service life:

And the Number One cause of tyre failure:

Puncture preventative products have been developed to address this problem statement. However

the heavens have also automatically solved the various problems caused by excessive heat

in normal tyres with their amazing cooling capacity.�@ This is not a man-made solution, but a

heaven sent one. Therefore, no one can be proud of it.

K) Lastly:

After a factory visit to a Retread tyre manufacturer in December 2019,�@ I visited the JAPAN RE-

TREADER'S ASSOCIATION office in Tokyo and met with the Secretary General Shikada. I had

made an appointment in advance. The purpose of my visit was to ask him about the state of the

retread tyre industry in Japan and the problems that I had identified during my visit to the re-

tread tyre factory. The discussion with him was very useful for me. Because he had the most ad-

vanced technology of the tyre.�@�@Therefore, it was a very useful opportunity for me to hear

the opinions of experts on the matter of SELLA.�@�@ For, he was a Bridgestone tyre engineer

working at the forefront as a tyre engineer for the Linear Shinkansen,�@�@�@which runs at a

speed of 500 km/h. The opening is scheduled for 2027.�@ The discussion with him, went well

beyond the reserved time. In this context, he feels that 150% tyre life is only a pipe dream. He

said that it would take more than 10 engineers working hard and bloody hard every day for

a tyre manufacturer to increase tyre life by 10%, and that it would take 10 years.

I would like to reiterate that 150% tyre life is truly a miraculous,�@completely inhuman and

outstanding technology. It is truly a gift from heaven, beyond human knowledge.

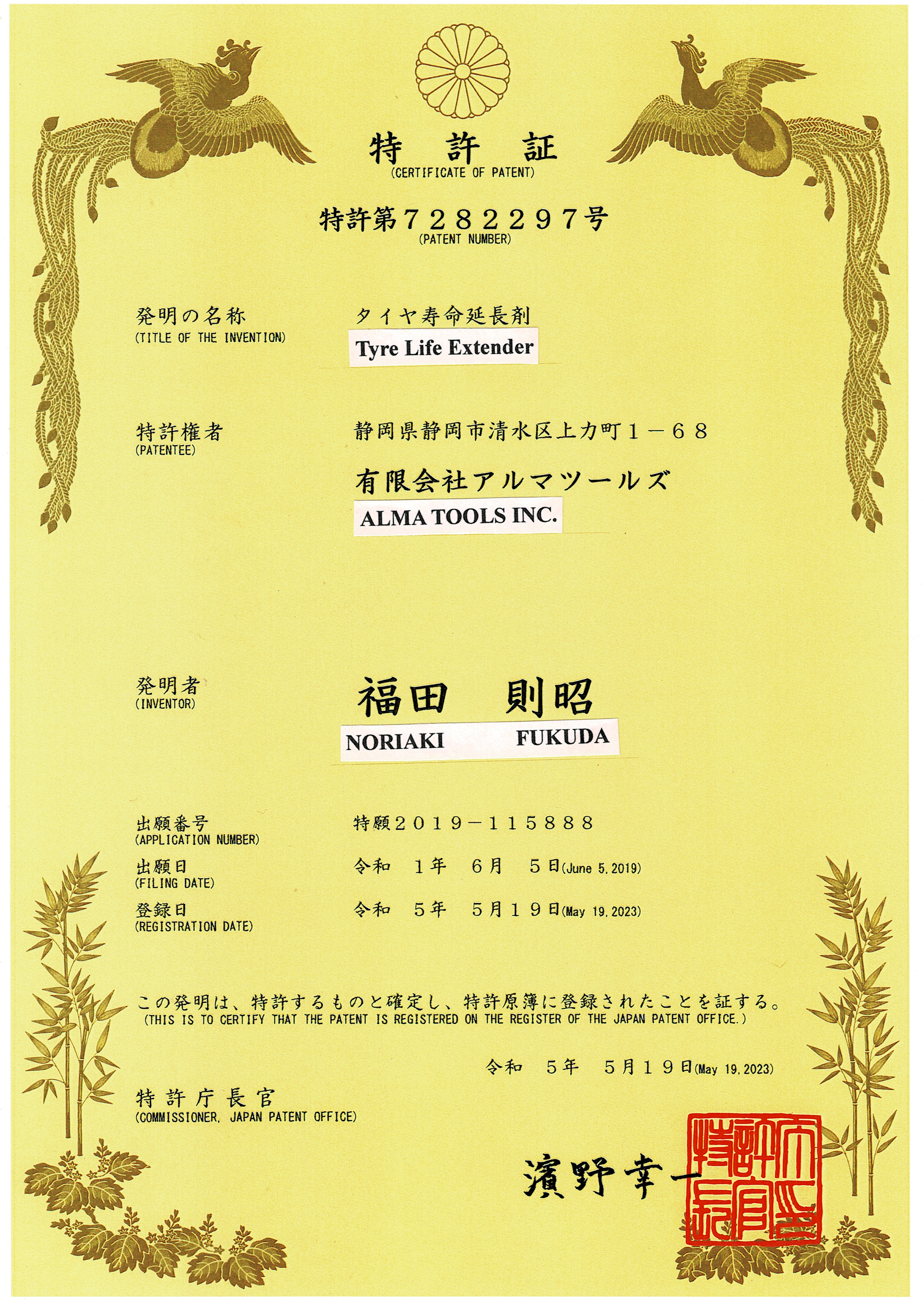

Special Notice:

I'm pleased to share with you the good news. It was patented by SELLA TSP.

�@PAT No.7282297 �@May 19, 2023 �@Tyre Life Extender

�@�@�@�@�@ �@ �@�@�@ �@�@ President �@�@�@ �@�@Noriaki Fukuda

�@�@�@�@ �@ �@�@�@ �@�@�@ Techinal Adviser�@�@ Teijiro Wakatsuki

|

Copyright © All rights reserved.

|

| |